The Peragrene Solution

1. RS2002 Binder

2. Concrete & Process Technology

3. Training & Support

The Peragrene team combines decades of proven experience in cement chemistry innovation and hands-on operational experience delivering exceptional road and airport repairs.

Our team of chemists and engineers have extensive international experience and a deep understanding of customer needs from project design and specifications to the execution of any type of work on roads and airports worldwide.

Through our network of global partners, Peragrene Binder RS 2002 can be produced at multiple international locations, ensuring it is readily available anywhere.

Ideal for time critical concrete projects including airports, roads, rail, defence, marine and tidal affected environments.

Peragrene Binder

Peragrene RS2002 is an engineered binder used to produce Rapid Strength Concrete. Peragrene reduces project delivery time by developing significant strength in as little as 2 hours. This ensures minimal disruption to the asset users and minimises lost revenue to the asset owner. This accelerates project delivery time, completing works faster, minimising site downtime and saving money over the entire project life.

*High Early Compressive Strength 30MPa in 2 hours

*High Early Flexural Strength 4.1 MPa in 2 hours

*Very low Water Penetration – Less than 3mm

*Superior chloride migration resistance <4m2/s

*Controlled setting times in a range of ambient temperatures – 2°C to 35°C

*Typical Concrete Results

Features

Flexibility

Suitable binder replacement for a range of concrete mix designs.

Versatility

Suitable for a wide range of time-critical applications.

Innovation

Utilising the latest world leading CSA-based ternary binder technology.

Sustainability

Lower embodied CO2e and increased design life.

Durability

Very low water permeability and superior chloride resistance.

Robustness

Can be applied and performs in a range of extreme weather conditions.

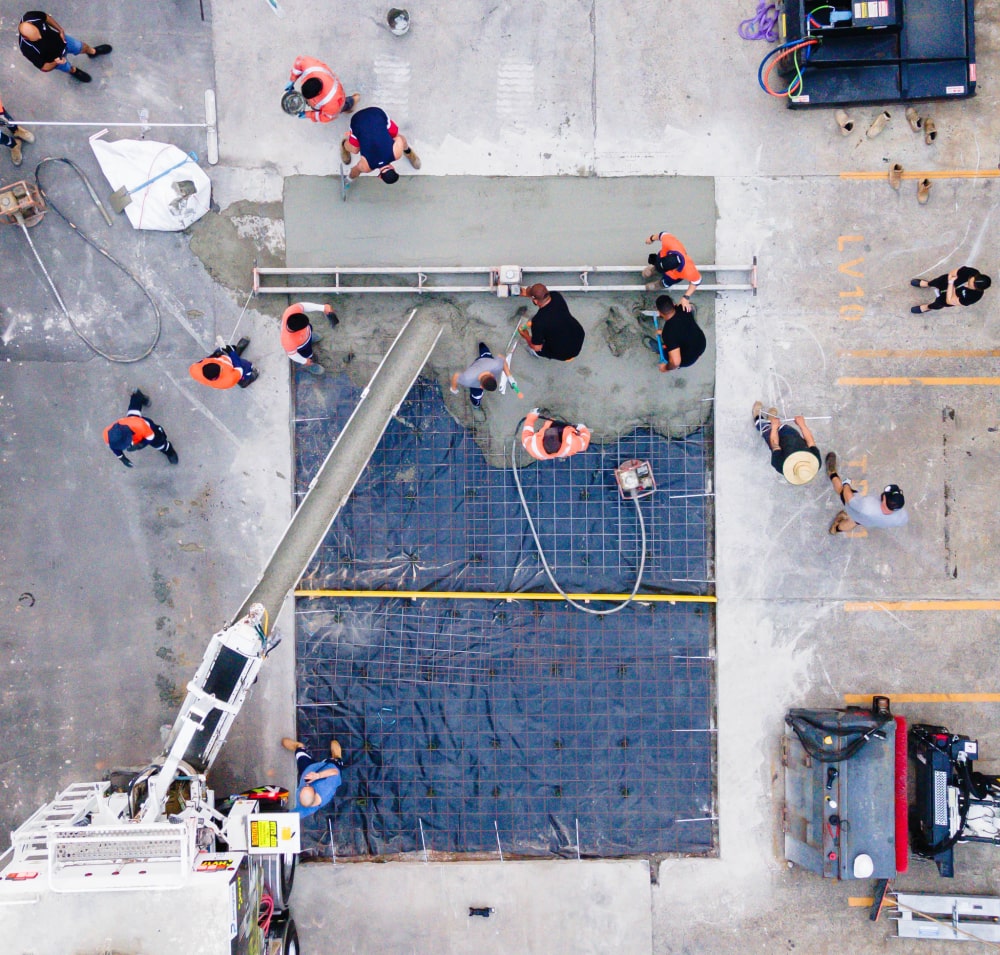

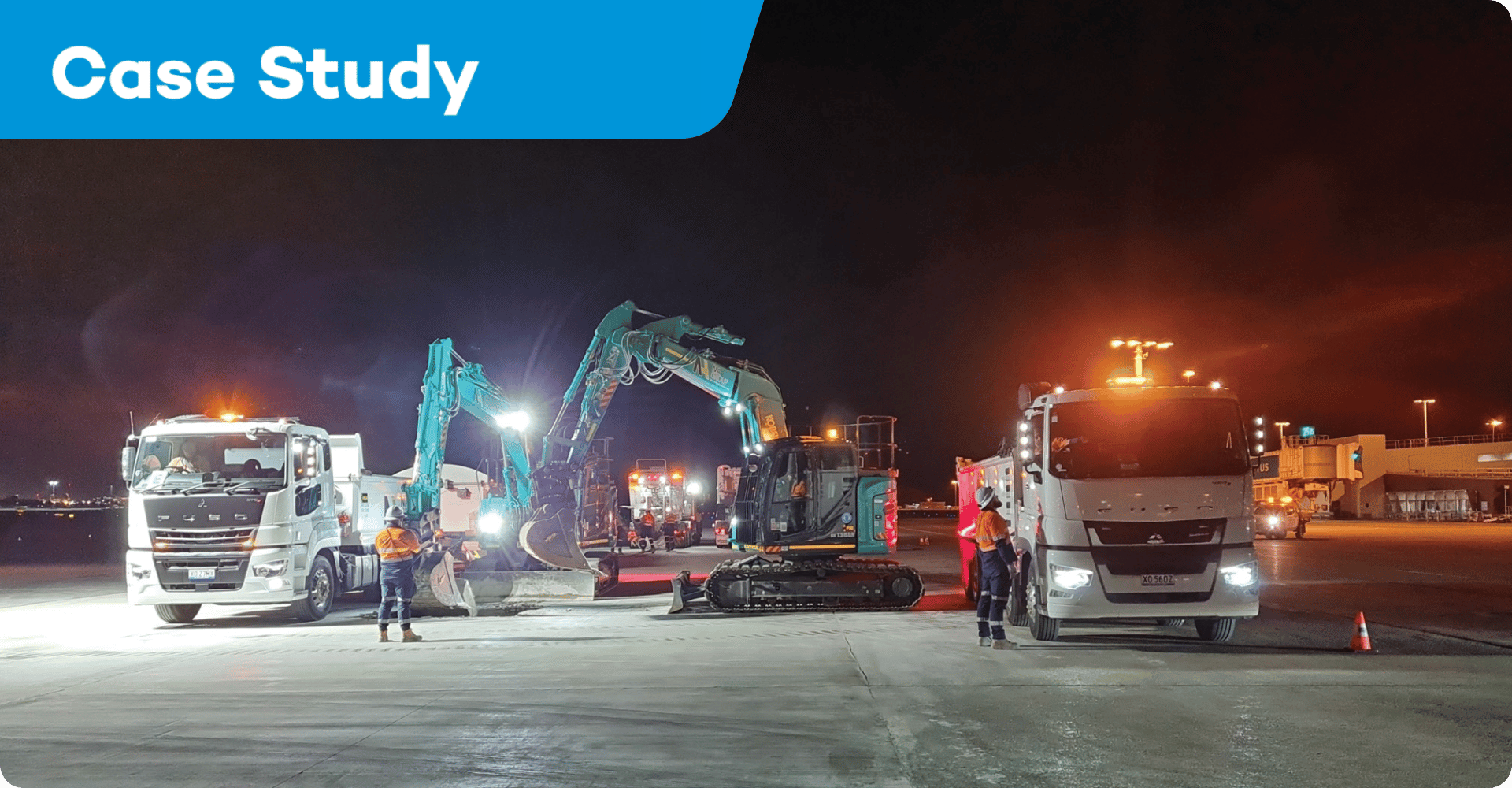

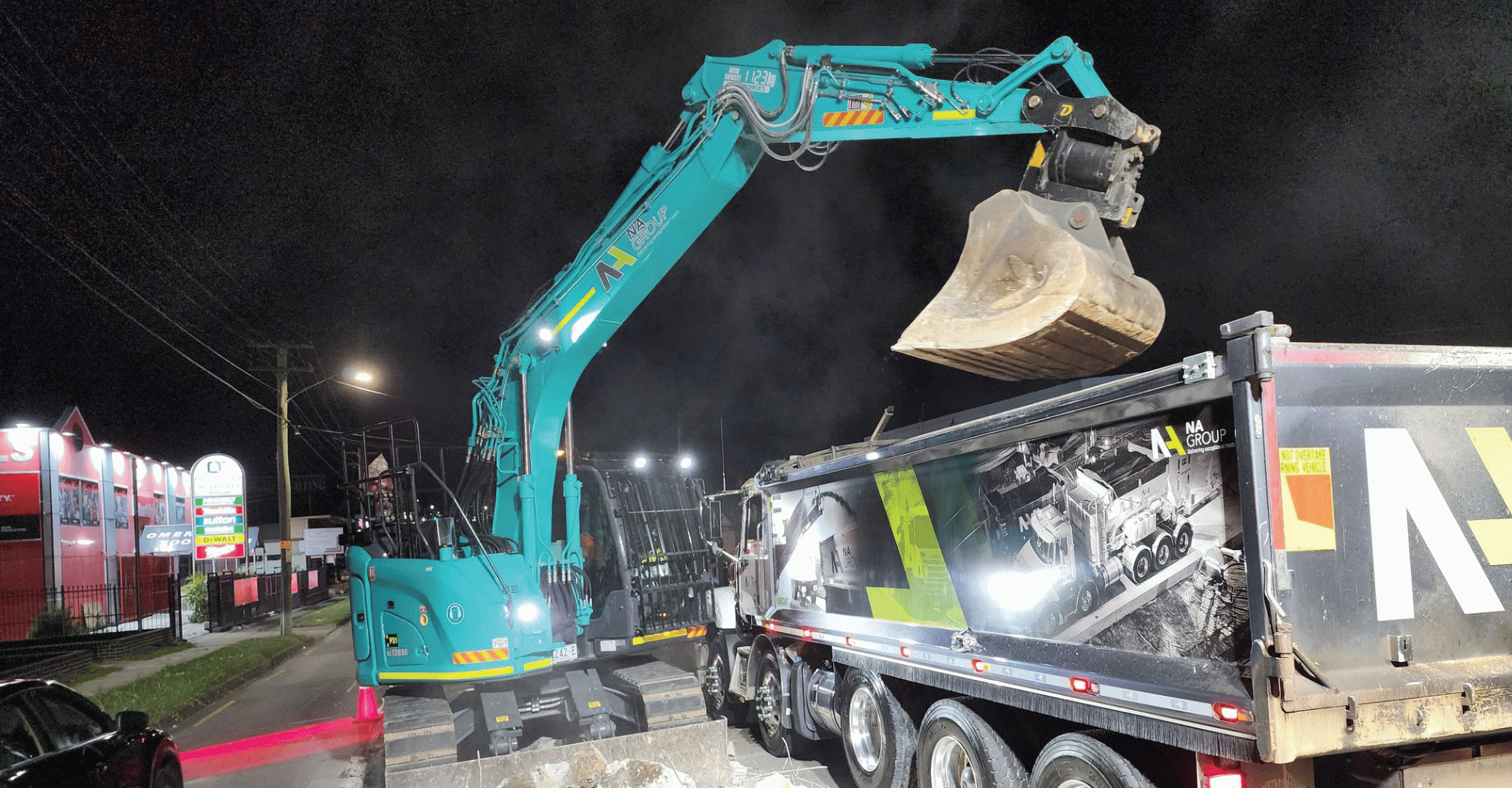

Case Study

Peragrene was used by Sydney International Airport to replace 230m3 of deteriorated concrete slabs on Runway 25 within a strict 11pm – 5am curfew. Using Peragrene high early-strength concrete, which achieves 30 MPa in two hours. Rigorous quality assurance, including pre-testing and real-time testing during pours, guaranteed durability and compliance with operational standards. By leveraging advanced technology and efficient execution, NA Group delivered a high-quality, durable runway surface ahead of schedule, meeting the airport’s stringent requirements.

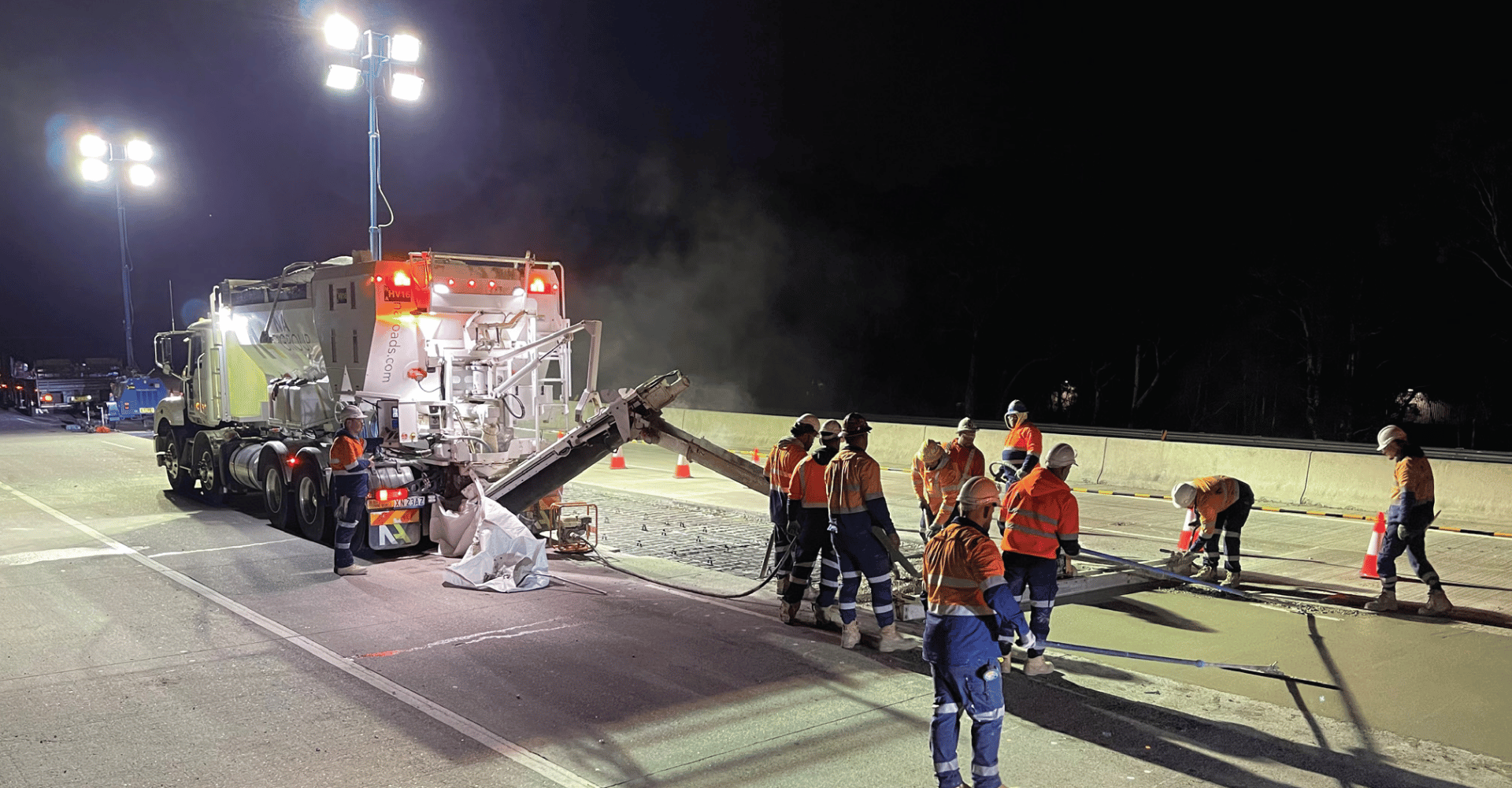

Case Study

An 8-month project to demolish, remove, and replace 70 concrete slabs on the M5 Southwest Motorway, a critical transit route in Sydney, while adhering to strict nightly curfews from 11 pm to 4 am to avoid disrupting heavy daily traffic. Using Peragrene high early- strength concrete, which achieves trafficable strength within 2 hours, the team followed a precise hour-by-hour schedule to meet tight deadlines and avoid steep penalties of $11,000 per hour, per lane. Rigorous quality assurance protocols, including pre-testing and on-site checks, ensured the slabs met durability and load-bearing standards, allowed lanes to reopen by 4 am each morning, minimising public inconvenience and ensuring a safe work environment.

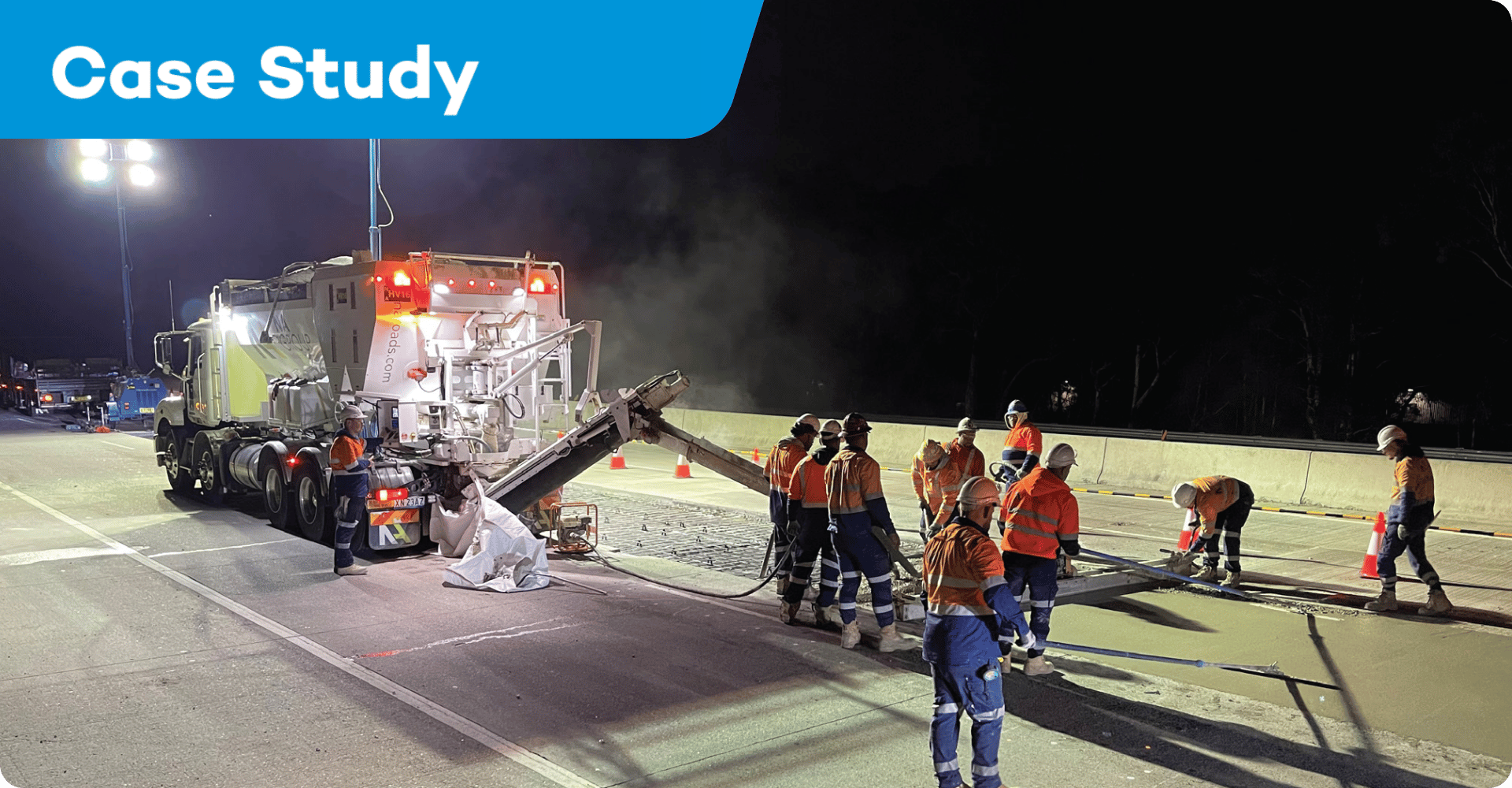

Case Study

With an installation of multiple concrete layers, culminating in an asphalt surface, on 1.5 kilometers of King George Road in Sydney, a vital arterial route. Using Peragrene high early-strength concrete, the team efficiently executed night-only operations, completing all structural layers-including sand-cement, lean mix, base, and asphalt-within each shift from 11 pm to 5 am, ensuring the road reopened to traffic every morning. The rapid setting properties of Peragrene allowed for quick curing and load-bearing strength, enabling seamless progression through layers while minimizing public inconvenience.

Training & Support

With extensive technical and operational experience, the our team can assist you to integrate the Peragrene Rapid Strength Concrete solution to into your business.

We offer training and end-to-end support throughout the process including:

- guidance on concrete mix design

- equipment setup

- resourcing

- project staging

- placement and finishing of concrete.

Recent projects