M5 South West Motorway Concrete Slab Replacement

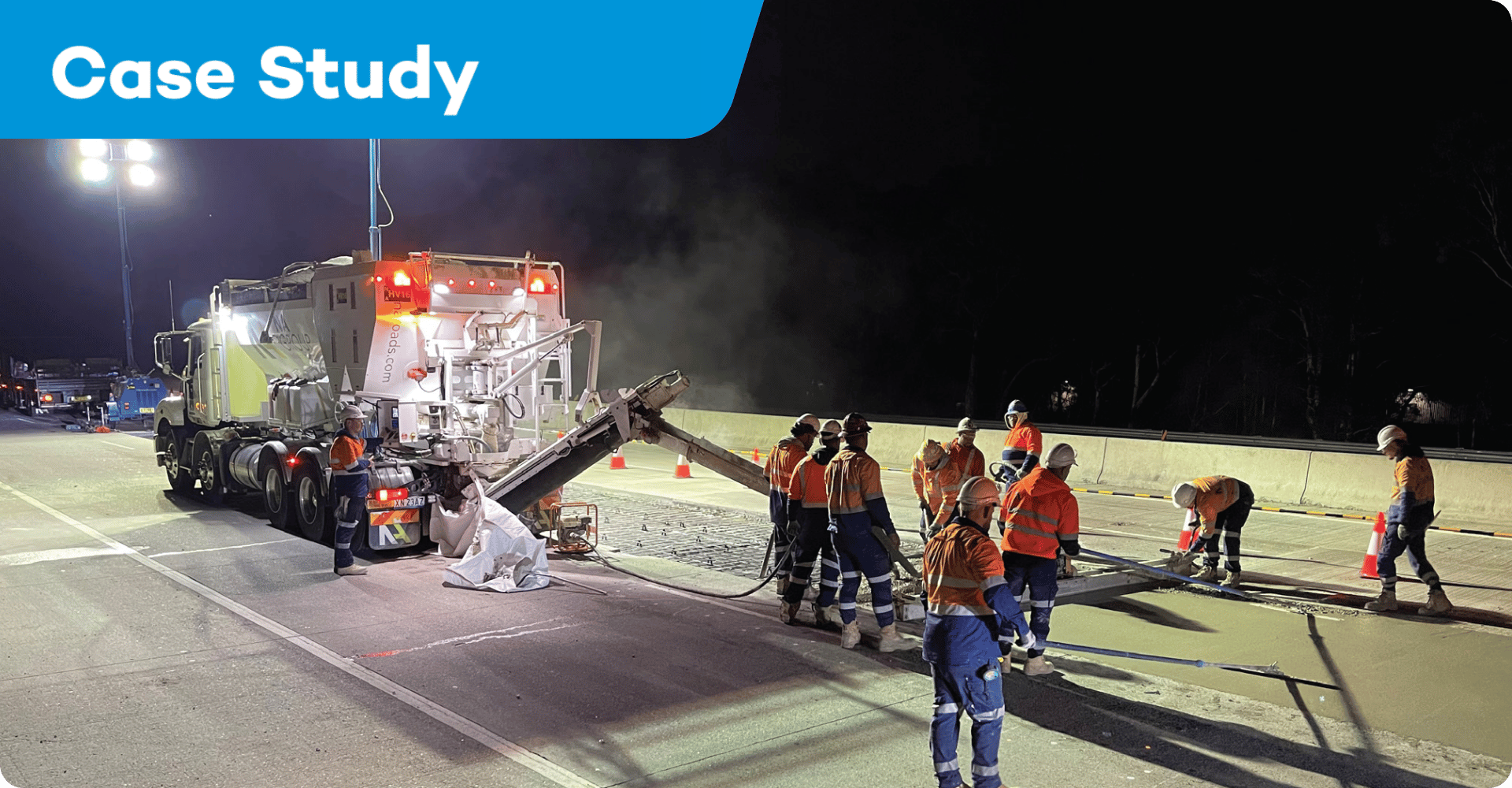

NA Group was engaged to demolish, remove and replace 70 concrete slabs along the M5 Southwest Motorway, a critical transit route in Sydney. The project spanned 8 months, requiring NA Group to deliver consistent, high-quality results across night shifts, despite varying seasonal conditions from winter through to summer. Due to the motorway’s heavy daily traffic, our team adhered to strict nightly curfews, with work beginning at 11 pm and all lanes reopened by 4 am, preventing any disruption to commuter and freight traffic.

Precise Scheduling Under Strict Curfews and Penalties

Time management was critical, as each shift had an absolute deadline of 4 am, with no extensions permitted. Penalties for delays were steep, incurring fines of $11,000 per hour, per lane. To mitigate this risk, we developed an hour-by-hour programme, outlining every step from site preparation to final inspection. This highly disciplined schedule was enabled by our use of Peragrene high early-strength concrete, which reaches a trafficable strength within 2 hours, allowing us to meet all installation and finishing requirements within the tight nightly window. This controlled timeline ensured the entire work zone was cleared and lanes were fully reopened by morning, without delay penalties. By maintaining strict adherence to our project plan, we were able to efficiently manage resources and ensure traffic flow continuity for the M5 Motorway.

To mitigate ambient temperatures fluctuation from winter lows to summer highs, we utilised a varying dose of retarder to adjust the mix design, allowing for precise control of the concrete setting time and early strength development in all conditions.

These batching units feature computerised controls, providing repeatable, high- quality results and real-time adjustments on-site. By ensuring the mix adapted to seasonal temperature variations, we achieved consistent curing rates and reliable strength gains each night.

For a high-traffic motorway like the M5, durability and load-bearing capacity were essential to meet the rigorous specifications required by road infrastructure authorities. NA Group implemented strict quality assurance protocols to ensure that each slab met the project’s strength and density specifications. Before work commenced, we conducted extensive testing of Peragrene under controlled conditions to verify its load-bearing capabilities and early strength performance.

During each shift, our team carried out additional on-site tests, including cylinder strength, density checks, and curing rate assessments, to confirm that every batch met the required standards. By maintaining stringent quality checks throughout each phase of the project, we were able to provide a robust, long-lasting concrete solution tailored to withstand the heavy vehicular load of the M5 Motorway.

Given the motorway’s high traffic volume and frequent commuter usage, NA Group prioritised traffic safety through carefully managed traffic control measures. During each shift, traffic was slowed from 100 km/h to 40 km/h around the work zone, ensuring the safety of both motorists and crew. Clear signage and detours were implemented, directing traffic safely around our work area.

Our teams mobilised rapidly each night, with all required personnel and equipment ready on-site prior to the 11 pm start time. With precise planning and the use of fast-setting Peragrene, we minimised lane downtime, allowing traffic to flow normally by 4 am each morning. This approach was crucial in limiting disruptions to daily motorway operations while ensuring a safe and efficient work environment.

The versatility of our mobile batching units paired with Peragrene Rapid Strength Concrete provides the capabilities of delivering high early strength concrete to metropolitan and remote locations. Each unit can store up to 50 mix designs and supply on demand continuous concrete pouring allowing consistent results across varying temperatures.