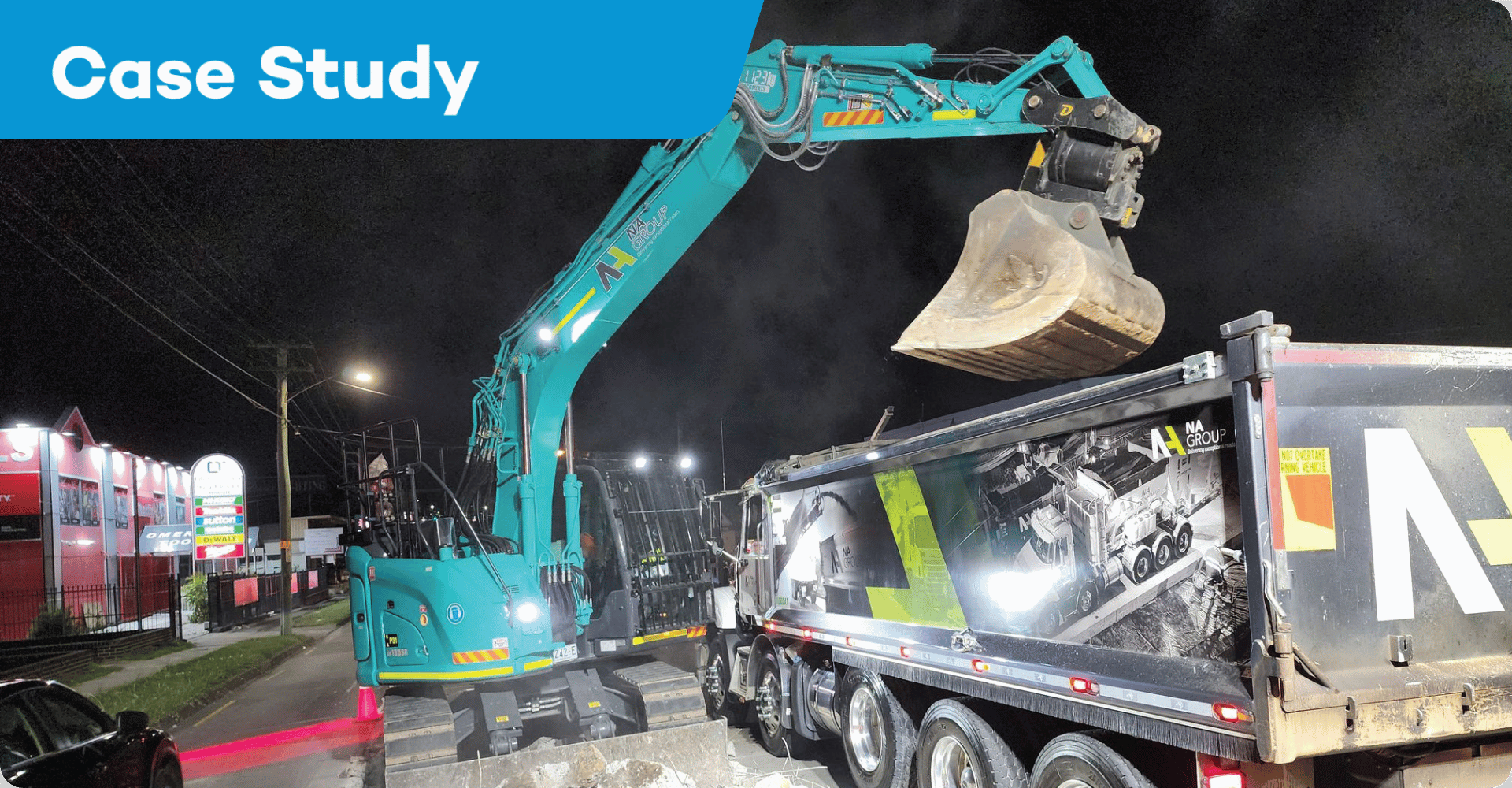

King Georges Road Concrete Slab Replacement

NA Group was engaged to excavate, dispose of, and lay multiple layers of concrete, resulting in an asphalt surface on 1.5 kilometres of King George Road in Sydney, a vital arterial route. Given the road’s importance, the project demanded an efficient strategy that allowed for night-time operations to complete all structural layers without disrupting daytime traffic. By employing Peragrene high early-strength concrete, we successfully finished all layers-including asphalt, base, lean mix, and sand-cement-within each night shift, thereby reopening the road to motorists by morning. This approach ensured the continuous flow of traffic on King George Road while providing a durable and long- lasting pavement solution.

Layered Structure in a Time-Restricted Environment

Due to the major road’s high usage, the project demanded rapid installation of multiple structural layers within each shift. Starting at 11 pm, we completed the entire sequence-from sand-cement foundation to asphalt surface-by the time the road reopened at 5 am. This layered structure included:

Sand-Cement Layer: The foundation was laid down swiftly as a stabilising layer for further structural support.

Leanmix Concrete Layer: Using Peragrene in the leanmix layer allowed rapid set times and immediate strength gains, providing a stable base for the upper layers.

Base Layer: Also utilising Peragrene, the base provided robust support, achieving required compaction and early strength in a single shift.

Asphalt Surface: Finally, we applied the asphalt, completing the structure with a durable, smooth driving surface ready for daily traffic.

Working within a strict time window each night required materials that would meet both curing and load-bearing needs immediately after application. Peragrene’s high early-strength properties enabled us to achieve necessary strengths for both the leanmix and base layers quickly, allowing us to proceed with subsequent layers without delay. This process was repeated across multiple shifts, with each shift’s work fully completed and the road reopened for traffic flow every morning. The rapid set times of Peragrene facilitated an efficient workflow and supported a smooth, night-only operation schedule, minimising public inconvenience.

Given the structural demands of King George Road, our team implemented comprehensive quality checks to ensure each layer’s adherence to project specifications. The use of Peragrene in the leanmix and base layers delivered the required compaction and durability. Prior to full-scale installation, we conducted test pours and curing tests to confirm each layer’s performance under real-world conditions, meeting the high standards required for long-term durability on a high- traffic route.

Throughout each shift, quality testing included on-site compressive strength tests, curing rate assessments, and surface inspections to verify uniformity and layer stability. This quality-focused approach assured that every layer would contribute to a resilient, high-quality pavement structure suitable for King George Road’s continuous heavy vehicle and commuter traffic.

On-site concrete mixing allows us to reduce waste and an increase efficiency as the crew adjusts mix design and amount in real time. Our mobile batching unit technology ensures that our projects run seamlessly and deliver outstanding quality and efficiencies.

Quality Reports

(days)

(MPa)