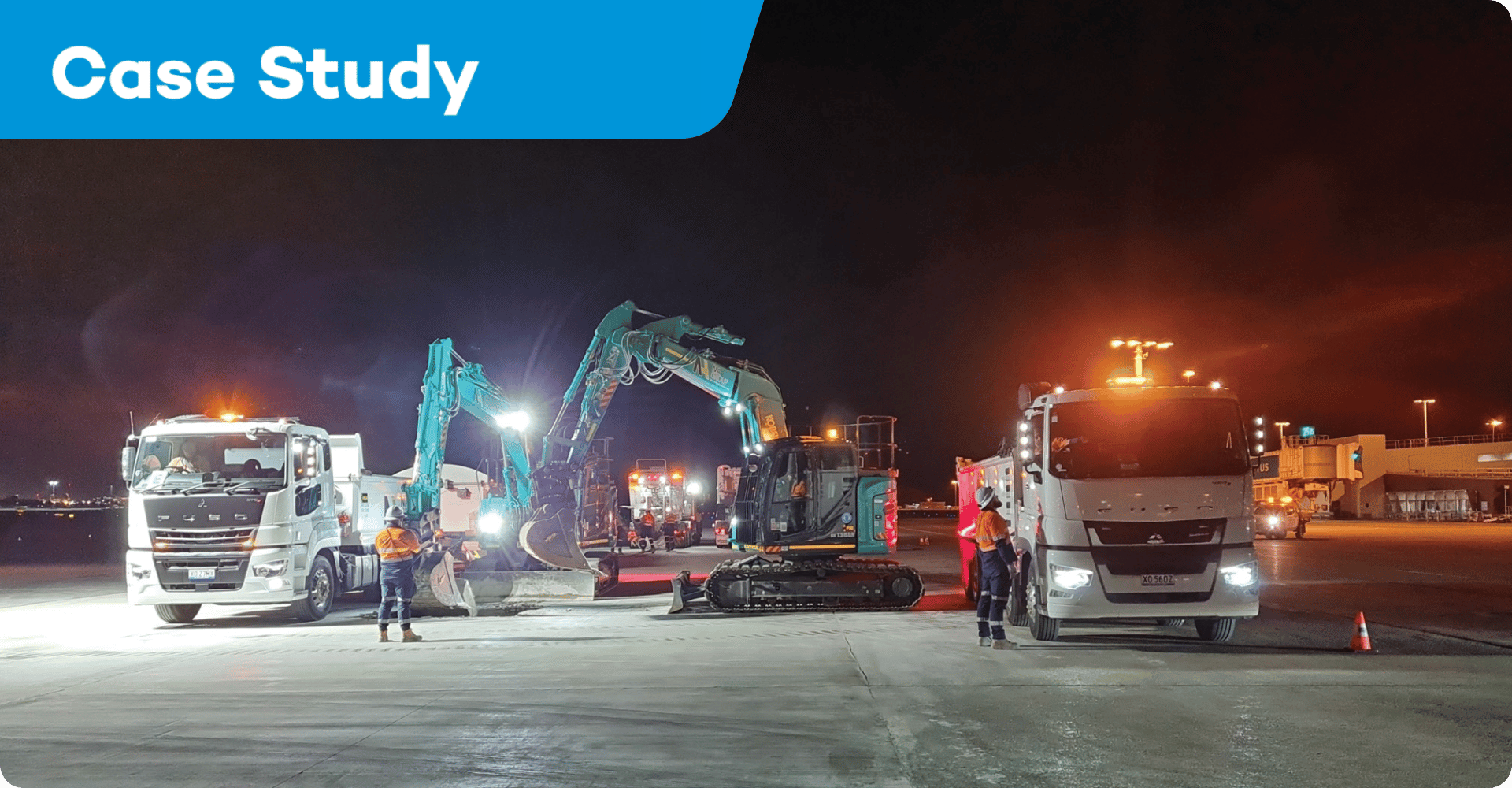

Sydney International Airport Concrete Slab Replacement

NA Group were appointed by Sydney International Airport to demolish, remove and replace a total of 230m3 deteriorated concrete slabs on Runway 25. This project required precise, overnight work within strict curfew hours to avoid disruption to airport operations, with all works completed between 11 pm and 5 am. The challenge was to install a high-quality, durable concrete surface that would be trafficable by 5 am, requiring a concrete solution with a fast set time and superior early strength. We deployed Peragrene, a high early-strength concrete that reaches 30 MPa within two hours, enabling rapid trafficability with minimal downtime.

Optimising Time-Critical Operations for Runway Readiness

Given the short timeframe, each step in the slab replacement process was optimised to fit within the restricted six-hour window. By precisely planning each phase of work and deploying our experienced personnel alongside advanced equipment, we ensured each shift could be executed smoothly. Operations commenced the moment clearance was granted by airport management, with teams mobilised and positioned for immediate action.

With our mobile batching units, we achieved on-demand mixing and ensured an uninterrupted supply to each slab pour and by using Peragrene. This enabled us to expedite the curing process, allowing the team to complete necessary steps for surface finishing, inspection, and cleaning well before the runway reopening deadline. This scheduling meant that concrete installation was consistently completed ahead of time, enabling thorough inspections and any final adjustments before clearing the runway for traffic.

Maintaining Consistency in Environmental Conditions

To mitigate environmental impact, we adjusted the Peragrene mix on-site according to the ambient temperature, aided by our mobile batching units’ advanced controls. This capability allowed precise control over each batch’s mix design, ensuring consistent set times and strength gains across varying night-time temperatures.

Adjusting for environmental factors ensured that each slab met the same performance criteria despite Sydney’s fluctuating seasonal conditions. This adaptability was critical to maintaining uniformity and reliability in the concrete’s curing and hardening process, directly supporting the airport’s requirement for dependable, repeatable results regardless of temperature shifts.

Ensuring High Standards in Quality and Testing

The demands of a critical infrastructure setting, such as a runway, require best-in- class quality assurance to guarantee both durability and safety under heavy and repeated loads. To uphold these standards, we performed multiple rounds of testing to confirm the concrete’s strength, resilience, and performance characteristics.

To validate Peragrene’s suitability, we pre-tested a slab at our facility, with detailed inspections conducted by Sydney Airport stakeholders before work commenced. During each pour, we carried out cylinder, maturity, and flexbeam tests, providing real-time verification that each slab met required specifications for load-bearing strength, density, and finish.

With airport stakeholders on-site for these tests, we maintained transparent quality control and ensured alignment with Sydney Airport’s operational standards. Additionally, our mix design received prior approval, providing a clear baseline for all testing and reinforcing consistency across each pour. Each slab was further inspected and cleaned by our team before runway handover, meeting the airport’s high expectations for finished surface quality and longevity.

Peragrene Rapid Strength Concrete accelerates the construction process by developing significant strength in as little as 2 hours. This accelerates project delivery time, completing works faster, minimising site downtime and saving money over the entire project life with a 100-year design life.

Quality Reports

(days)

(MPa)

(days)

(MPa)

(days)

(microstrain)